Engineering change management is a critical process in product development that involves managing design changes and engineering change orders (ECOs)

-

CADCAM-E

-

Blog

-

Change-management

Streamlining Engineering Change Management: Effective Strategies for Managing Design Changes

Engineering change management is a critical process in product development that involves managing design changes and engineering change orders (ECOs). Effective change management ensures that design modifications are implemented smoothly, minimizing disruptions, and keeping the product development on track. It is essential for successful product development, maintaining product quality and problem solving. Managing design changes and engineering change orders requires careful coordination across teams, effective communication with key stakeholders, and a well-defined organizational change management model.

In this article, we will explore how ReVue can be used to streamline engineering change management, ensuring that design changes are efficiently managed throughout the product lifecycle without the overheads and burdens imposed by traditional Product Data Management and Change Management software. But before we do that, it’s imperative that we gain a good understanding of Change Management, its basic principles and how it applies to engineering design changes.

What is Change Management?

“Change management” in engineering product development is crucial for addressing design errors, adapting to market demands, and ensuring the successful implementation of design changes. It refers to the systematic process of managing and implementing modifications or design changes throughout the life cycle of a product. It involves coordinating efforts, evaluating the impact of changes, and ensuring that the product development stays on track while maintaining product quality and meeting customer requirements.

By establishing clear business processes, engaging stakeholders, estimating costs, and leveraging technology, organizations can streamline change management and maintain product development on track while delivering high-quality products.

The engineering change process typically involves several stages. It begins with the identification of the need for a change, which could arise due to design errors, customer feedback, or evolving market demands. Once the need for change is identified, it is essential to estimate the costs, resources, and potential impact on components and documentation. This stage helps organizations evaluate the feasibility and impact of implementing the design change.

Subsequently, the engineering change order process is initiated, where detailed plans are developed, and the change is implemented. Throughout this process, effective communication and collaboration among team members, key stakeholders, and the Change Control Board (CCB) are crucial for successful organizational change management and problem solving.

Why is Change Management Important?

Change management is crucial in engineering product development for several reasons. Firstly, it helps address design errors or issues that may arise during the development process. By promptly identifying and resolving these issues through effective change management, organizations can prevent costly rework and potential setbacks.

Engineering change management plays a crucial role in maintaining product development on track and ensuring that design modifications are implemented smoothly. It encompasses processes and tools that allow organizations to manage design changes effectively, minimizing disruptions, problem solving and maintaining product quality. By implementing robust business processes, organizations can address design errors, accommodate customer feedback, adapt to evolving market requirements, and enhance their product support. Effective change management helps maintain strong collaboration across teams and the supply chain, ensuring that design changes are implemented seamlessly and on time.

Furthermore, it ensures that product development remains on track and aligned with project goals and objectives. It allows organizations to adapt to evolving market demands, customer feedback, and technological advancements. By embracing change and managing it effectively, companies can stay competitive and deliver products that meet customer expectations.

Effective organizational change management also fosters collaboration among key stakeholders, including the product team, supply chain partners, and change control board (CCB). It facilitates communication, decision-making, and consensus building, ensuring that all parties are aligned and informed throughout the change process.

How to implement Change Management?

Implementing the right strategies and model for change management is critical for the success of any product development effort. Here are some ways to effectively implement change management in your organization:

-

Establish a Clear Change Management Process

: Define a structured process that outlines the stages of the engineering change process, from identification to implementation. This process should include roles and responsibilities, communication channels, and decision-making protocols. Documenting and standardizing the process will ensure consistency and clarity.

-

Engage Key Stakeholders

: Involve key stakeholders from various departments and teams, including the product team, supply chain, and management board (CCB). This collaboration helps gather diverse perspectives, evaluate the impact of changes, and make informed decisions. Regular meetings and checkpoints with stakeholders can facilitate effective organizational change management.

-

Evaluate Impact and Estimate Costs

: Assess the impact of proposed changes on various aspects, such as components, documentation, and engineering services. Estimate the costs and resources required for implementing the changes. This evaluation will help prioritize changes based on feasibility, impact, and available resources.

-

Communicate Effectively

: Communication is vital throughout the change management process. Regularly update and inform team members and stakeholders about the status of changes, decisions made, and any necessary actions. Transparent and timely communication ensures that everyone is on the same page and aligned with the organizational change management objectives.

-

Leverage Technology

: Utilize technology solutions, such as Product Lifecycle Management (PLM) software, to streamline change management. PLM systems centralize product-related information, including CAD files, documentation, and change history. This allows for easier collaboration, access to up-to-date information, and efficient change tracking.

-

Monitor and Review

: Continuously monitor the implementation of changes and their impact on product development. Regularly review the effectiveness of the business processes and make necessary adjustments. By monitoring and reviewing, organizations can identify areas for improvement and optimize the organizational change management approach.

What is Engineering Change Management?

Engineering change management is a systematic process that focuses on managing and controlling modifications or changes to engineering designs, business processes, and systems. It encompasses the evaluation, documentation, approval, and implementation of these changes, ensuring that they are effectively incorporated while minimizing disruptions and maintaining the overall integrity of the engineering product or project.

Engineering Change Management Benefits

Engineering change management offers numerous benefits, including error prevention, improved collaboration and problem solving, adherence to schedules and budgets, enhanced product quality, and compliance with regulations. By implementing effective organizational change management practices, organizations can navigate the complexities of design modifications and maintain a streamlined and efficient engineering process. Some key benefits include:

-

Minimizing Errors and Rework

: Through proper change management practices, potential design errors or issues can be identified and addressed early on. This helps minimize costly rework and ensures that the final product meets the desired specifications and quality standards.

-

Enhancing Collaboration and Communication

: Engineering change management involves engaging key stakeholders, including design teams, manufacturing, supply chain, and management. This fosters collaboration, promotes effective communication, and ensures that all parties are informed and aligned throughout the change process.

-

Maintaining Project Schedule and Budget

: By implementing change management strategies, organizations can better estimate the impact of changes on project timelines and budgets. This allows for proactive planning, resource allocation, and risk mitigation, ensuring that project objectives are achieved within the defined constraints.

-

Improving Product Quality and Customer Satisfaction

: Effective organizational change management helps in incorporating customer feedback, market demands, and technological advancements into the product design. By adapting to evolving needs, organizations can enhance product quality, meet customer expectations, and gain a competitive edge in the market.

-

Ensuring Compliance and Regulatory Requirements

: In industries with strict regulatory frameworks, engineering change management becomes crucial for ensuring compliance. Proper documentation, traceability, and validation processes help organizations adhere to legal and safety standards, avoiding potential penalties or legal issues.

Design change management procedure in five easy steps

Managing design changes effectively is crucial for maintaining product integrity and ensuring successful product development. Here are five easy steps to establish a design change management procedure:

-

Identify and Assess

: Identify the need for a design change and assess its impact on the product. Consider factors such as feasibility, cost, and potential risk.

-

Plan and Document

: Develop a detailed plan outlining the steps, resources, and timeline required for implementing the design change. Document all aspects of the change, including specifications, design modifications, and relevant documentation.

-

Review and Approval

: Present the proposed design change to key stakeholders, such as the change control board (CCB), for review and approval. Address any concerns or questions raised during the review process.

-

Implement and Test

: Execute the approved design change and conduct thorough testing to ensure its effectiveness and compatibility with existing systems. Document any changes made during the implementation phase.

-

Communicate and Evaluate

: Communicate the design change to relevant team members and stakeholders, ensuring everyone is aware of the modifications. Evaluate the results of the change and gather feedback for problem solving and continuous improvement.

By following these five steps, organizations can establish a systematic and efficient procedure, enabling them to adapt to evolving requirements and maintain a successful product development process.

Implementing Effective Strategies for Engineering Change Management

To streamline engineering change management and manage design changes effectively, organizations can adopt several strategies. First and foremost, establishing clear management processes is crucial. This includes defining roles and responsibilities, establishing communication channels, and implementing a robust change management model. By documenting and standardizing these business processes, organizations can ensure consistency, clarity, and efficiency in managing design changes.

Involving key stakeholders from different departments and teams, such as the product team, supply chain, and product lifecycle management, is essential for successful change management. Regular meetings and checkpoints with the CCB can expedite decision-making processes and provide a forum for evaluating and approving design changes.

Additionally, leveraging technology solutions such as Product Lifecycle Management (PLM) software can greatly facilitate engineering change management. PLM systems allow organizations to centralize and manage all product-related information, including CAD files, documentation, and change history and improve problem solving and troubleshooting capabilities in case of design errors. This not only enhances collaboration among team members but also ensures easy access to up-to-date product information during the change management process.

Furthermore, accurate estimation of costs, resources, and potential impact is vital for effective change management. By conducting thorough assessments and involving relevant stakeholders, organizations can make informed decisions regarding the implementation of design changes.

Change Management with a difference

Streamlining engineering change management and effectively managing design changes are critical for maintaining product quality and meeting customer expectations. By implementing clear management processes, involving key stakeholders, and leveraging technology solutions, organizations can navigate the complexities of engineering change orders and keep their product development on track. Effective engineering change management ensures that design modifications are efficiently implemented, mitigating risks and maintaining high standards of product quality throughout the lifecycle.

However, “change management” as a function is handled in most organizations by complex enterprise software like PDM/PLM that can be daunting for small and medium-sized businesses to implement. These change management business processes are oftentimes rigid and need significant IT management and administration.

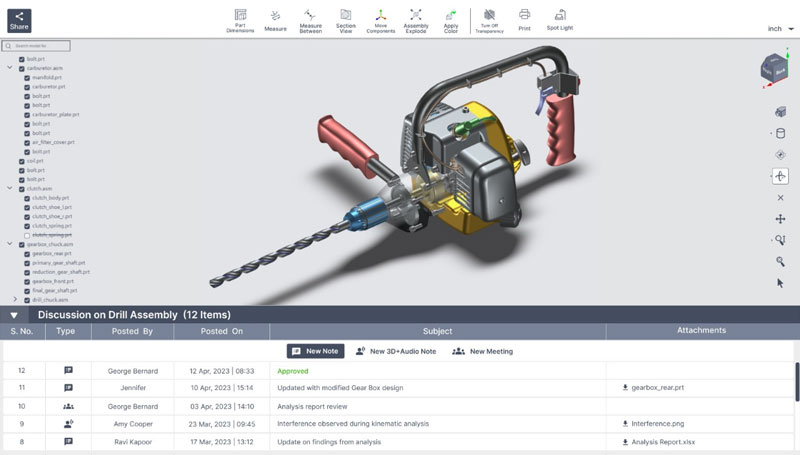

To address this, ReVue provides an alternate solution to manage design changes. It offers a rich set of features combined with an intuitive, visual user experience to share, track & manage changes within the company and with outside partners & suppliers without investing in complicated or pricey enterprise PDM/PLM software.

ReVue helps streamline engineering change management and cuts product development costs. With ReVue’s unique change management model, users can:

- Gain insights from all stakeholders

- Eliminate as-designed vs as-built errors

- Reach decisions quicker

- Reduce rework

- Improve design reuse